CIM class designs their own speakers

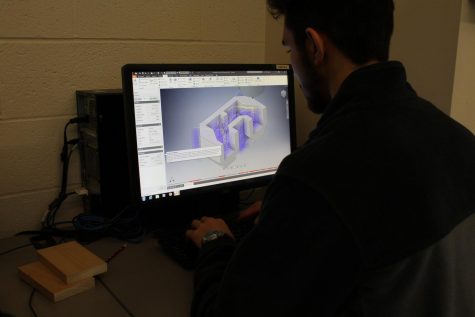

CIM students work with Autodesk Inventor software.

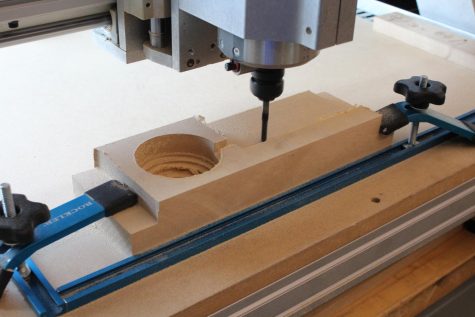

With the majority of the last nine weeks being spent learning how to program code for the CNC mill, it has finally come time for Mr. K’s CIM class to test themselves. Under the helpful eye of Mr. K, students began working on their own projects involving creating passive amplifiers using the CNC mill to carve out their creations.

The CNC mill is used to carve out the amplifiers.

At the beginning the nine weeks, the class began to learn how to manually code small designs onto their very own yo-yos. The task was quickly simplified when the class was introduced to the Autodesk Inventor software on the computers, which allowed students to design their very own creations with an extended amount of freedom. Students were assigned with creating passive amplifiers but could design them in any way they desired.

Dan Sounik designs his project using Autodesk Inventor.

Senior Dan Sounik described the process. “The CNC mill is the canvas and Autodesk Inventor is my paintbrush,” he said.

The class has recently begun the final stages of their projects and several passive amplifiers have been completed. Next, the class will design and create paddles with intricate designs meant for imprinting clay moldings for the Art Department. This class is always up to something interesting and should be a good fit for anyone wanting to explore engineering or manufacturing.

A CIM student works on his project as Mr. K oversees.

The YMCA ice rink is where you can find the ice hockey team's three-year varsity starter Nick Guimond, aka Nicky G. Nick is a senior and this is his second...